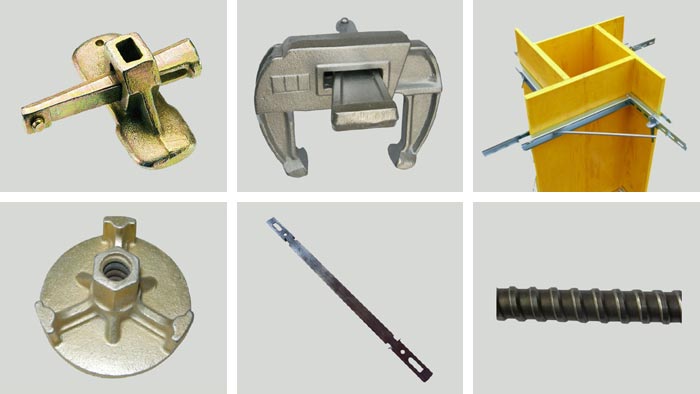

Otros accesorios

Useful for making work in any construction worksite easier and faster.

In this page:

GBM other accessories

Other accessories useful for your worksite.

Steel builder trestle

L 1m H 1-1,8m weight 13 kg

cod. AC12

Steel builder trestle

L 1m H 1-1,8m weight 13 kg

cod. AC13

Screw parapet

Full opening 80 cm upright height 100 cm Weight 5,6kg

cod. AC11

GBM building site wheelbarrow

Wheelbarrow for professional use in the building sector.

cod. AC14

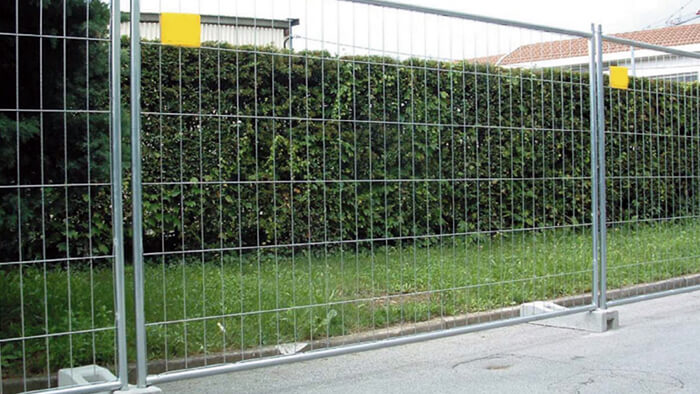

Mobile construction site fence

The mobile construction site fence di GBM it is the simple, fast and economic solution for fencing and delimiting areas, in compliance with current regulations, which prohibit tampering with roadways.

What is a mobile construction site fence

The GBM mobile construction site fence is a panel constructed with galvanized wire with a diameter of 3.10 mm and horizontal support poles in 30 mm diameter pipes and vertical support in 40 mm diameter pipes.

Ideal for preventing access to unauthorized personnel in construction site areas.

Our temporary construction site wire meshes comply with current regulations * on the safety and signage of work areas on temporary construction sites.

As regards the maneuverability of the products, thanks to the lack of roughness between the net and the pole, the risk of injury to operators is eliminated.

The mobile fence therefore turns out to be the simple, fast and economic solution when you have to fence and delimit areas, in compliance with the laws in force, which prohibit the alteration of roadways for the enclosure of work sites or for the delimitation, even temporary , of some areas.

*always comply with current regulations

Finishing

- GALVANIZED SENDZIMIR: The steel sheet used to produce the tube is subjected to a continuous galvanizing process in tanks containing pure zinc (called "Sendzimir") directly at the steel mill during the production phase.

- HOT GALVANIZED WIRE: The wire used for the construction of these fences is continuously hot-dip galvanized before welding by immersing in a zinc bath to ensure maximum resistance and durability over time for the product.

- PFZ: Hot dip galvanizing + Zinc salt phosphating + BASIC plastification

After hot dip galvanizing, the posts are sandblasted, greased and washed with demineralized water. The next step is the phosphating of the product which ensures greater resistance to corrosion and promotes the adhesion of the polyester resins after having carefully dried the stake. Finally, through polymerization, the layer of powder just deposited on the surface of the stake is fixed to the support.

Mobile fence

| Technical features | ||

|---|---|---|

| Frame size | mm | 3350 x 2000 H |

| Wire diameter (Ø) | mm | 3,10 |

| Mesh | mm | 100 x 300 H |

| Horizontal pipes diameter (Ø) | mm | 30 |

| Vertical pipes diameter (Ø) | mm | 40 |

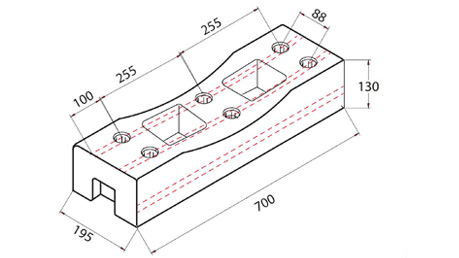

Concrete plinth for mobile fences

Concrete feet suitable for the connection and positioning of the fence modules.

GBM concrete plinth

Concrete plinth suitable for the connection and positioning of the fence modules.

They are equipped with 4 holes for fixing to the base of the panels.

Componente prefabbricato in calcestruzzo armato per l’impiego di recinzioni provvisorie, con 6 fori per palo Ø40 - Peso 28 Kg

Reinforced concrete base

| Technical features | ||

|---|---|---|

| Mechanical crush resistance (specimen compression cls) | 51,67 kN / mm² | |

| Filling concrete color | Uniform light gray shade | |

| Load-bearing capacity | R(N) = 15.92 RR(N) = 174.12 | |

| Water absorption | 4% | |

| Durability of the bearing capacity | Suitable for normal operating conditions | |

| Asbestos emissions | Not relevant for the intended use | |

| Aggregates used SAND | Not relevant for the intended use | |

| Concrete | certified by the quarry of origin according to UNI 9156 | |

Related products

News

GBM's shipbuilding scaffoldings

PUNTALES NECESARIOS PARA SOSTENER UN FORJADO GUÍA PARA ESTABLECER DISTANCIAS, CLASES Y CANTIDADES

Multidirectional scaffolding GBM certified EN 17067:2013

Contacto: información, precios y presupuestos.

¿Quieres más información sobre los productos GBM? ¡Pregúntanos!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)