In this page:

- About “push-pull” props,

- Features of “type L push-pull prop”,

- Type L1 push-pull props loads table,

- Type L2 push-pull props loads table,

- Features of “type N push-pull props”,

- Type N push-pull props loads table,

- Features of “type H push-pull prop”,

- Type H1 push-pull props loads table,

- Type H2 push-pull props loads table,

- Catalogue in pdf format.

About the “push-pull” prop

GBM push push-pull diagonal props consist of two telescopically slidable pipes.

The displacement thereof can be adjusted by means of a threaded ring nut and a pin inserted into the holes of the inner pipe.

This structure enables it to perform two actions, the classic pushing action (like normal props do) and the pulling action.

These elements are crucial for temporary and safe stabilisation of structures during the casting step, whether formworks, wooden panels, or prefabricated elements of various types.

GBM push-pull props come in three models.

Type L push-pull props: adjustment carried out using a double handle sleeve

Type N push-pull props: adjustment carried out using a single ring nut.

Type H push-pull props: adjustment carried out using two ring nuts.

GBM push-pull props come in three models:

Each of these models comes in variants with different sizes.

Do you want to download the summary table of GBM push-pull props in PDF format?

Features of the “Type L push-pull” prop

In the type L models, plumbing is carried out using a double handle sleeve. This model comes in two variants: Type L1 push-pull and type L2 push-pull

Type L1 push-pull

Type L1 push-pull prop: lighter prop, usually comes in the coated version with the aim of optimising the costs-benefits ratio given that it is used for propping light objects.

Features of the Type L1 push-pull prop:

Pipe protection: RAL 3009 red hot-dip coating with minimum durability in compliance with the ASTM D 2247-87 standard tests in a humidostatic chamber;

Inner pipe diameter 48 x 1.80 mm;

Outer pipe diameter 56 x 1.65 mm;

Type L2 push-pull

Type L2 push-pull prop: with greater thicknesses, it comes both in the hot dip coated version as well as the galvanised version (hot or cold dip galvanisation).

Features of the Type L2 push-pull prop:

- Pipe protection: hot-dip galvanization in compliance with the UNI EN ISO 1461 standard, with a guaranteed minimum thickness of 55 microns;

- Inner pipe diameter 48 x 3.00 mm;

- Outer pipe diameter 57 x 2.5 mm;

Both versions are characterised by:

- Extension adjustable between 1.80 and 5.00 m depending on the prop model, at 10 cm intervals by means of a double handle sleeve adjustment;

- Pulling guaranteed at 22.00 kN regardless of the use extension;

- Anti-shearing system: the greater length of the inner pipe with respect to that of the outer pipe enables guaranteeing an at least 10 cm difference between the two during the closing stage so as to avoid injury;

- Plates that can be articulated mounted on the two ends, so as to ensure the greatest adherence possible when fixing and mounting at multiple angles.

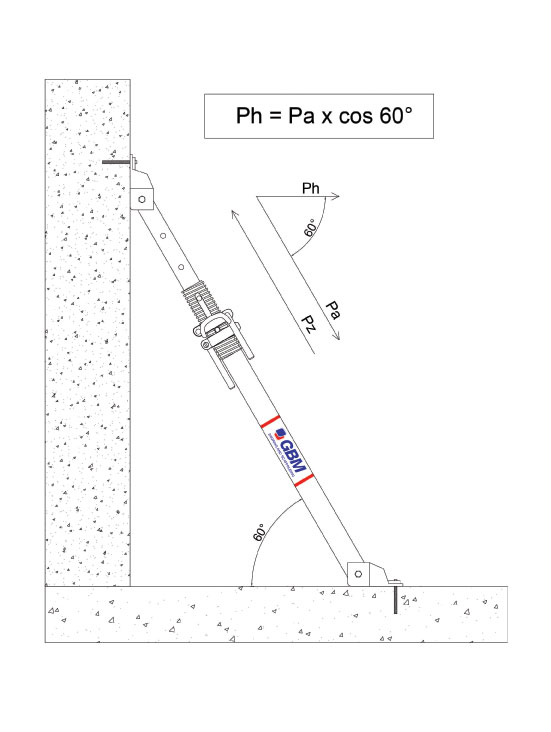

Type L1 push-pull props loads table

We - at GBM - manufacture 5 different types of L1 push-pull props models (PTS 3000 L1, PTS 3500 L1, PTS 4000 L1, PTS 4500 L1, PTS 5000 L1).

They are classified according to maximum extension and capacity. Below are their technical features.

| Ext. | PTS 3000 L1 | PTS 3500 L1 | PTS 4000 L1 | PTS 4500 L1 | PTS 5000 L1 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compr. | Traction | Compr. | Traction | Compr. | Traction | Compr. | Traction | Compr. | Traction | ||||||

| (m) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) |

| 5,00 | | | | | | | | | | | | | 1,90 | 3,80 | 23,60 |

| 4,90 | | | | | | | | | | | | | 2,00 | 4,00 | 23,60 |

| 4,80 | | | | | | | | | | | | | 2,10 | 4,20 | 23,60 |

| 4,70 | | | | | | | | | | | | | 2,25 | 4,50 | 23,60 |

| 4,60 | | | | | | | | | | | | | 2,35 | 4,70 | 23,60 |

| 4,50 | | | | | | | | | | 2,30 | 4,60 | 22,00 | 2,55 | 5,10 | 23,60 |

| 4,40 | | | | | | | | | | 2,45 | 4,90 | 22,00 | 2,70 | 5,40 | 23,60 |

| 4,30 | | | | | | | | | | 2,60 | 5,20 | 22,00 | 2,90 | 5,80 | 23,60 |

| 4,20 | | | | | | | | | | 2,75 | 5,50 | 22,00 | 3,10 | 6,20 | 23,60 |

| 4,10 | | | | | | | | | | 2,95 | 5,90 | 22,00 | 3,35 | 6,70 | 23,60 |

| 4,00 | | | | | | | 2,85 | 5,70 | 22,00 | 3,15 | 6,30 | 22,00 | 3,60 | 7,20 | 23,60 |

| 3,90 | | | | | | | 3,05 | 6,10 | 22,00 | 3,40 | 6,80 | 22,00 | 3,90 | 7,80 | 23,60 |

| 3,80 | | | | | | | 3,25 | 6,50 | 22,00 | 3,65 | 7,30 | 22,00 | 4,30 | 8,60 | 23,60 |

| 3,70 | | | | | | | 3,50 | 7,00 | 22,00 | 3,95 | 7,90 | 22,00 | 4,70 | 9,40 | 23,60 |

| 3,60 | | | | | | | 3,75 | 7,50 | 22,00 | 4,30 | 8,60 | 22,00 | 5,15 | 10,30 | 23,60 |

| 3,50 | | | | 3,75 | 7,50 | 22,00 | 4,10 | 8,20 | 22,00 | 4,70 | 9,40 | 22,00 | 5,75 | 11,50 | 23,60 |

| 3,40 | | | | 3,95 | 7,90 | 22,00 | 4,40 | 8,80 | 22,00 | 5,15 | 10,30 | 22,00 | 6,35 | 12,70 | 23,60 |

| 3,30 | | | | 4,20 | 8,40 | 22,00 | 4,80 | 9,60 | 22,00 | 5,70 | 11,40 | 22,00 | 6,90 | 13,80 | 23,60 |

| 3,20 | | | | 4,80 | 9,60 | 22,00 | 5,25 | 10,50 | 22,00 | 6,00 | 12,00 | 22,00 | 7,30 | 14,60 | 23,60 |

| 3,10 | | | | 5,25 | 10,50 | 22,00 | 5,80 | 11,60 | 22,00 | 6,50 | 13,00 | 22,00 | 7,60 | 15,20 | 23,60 |

| 3,00 | 5,10 | 10,20 | 22,00 | 5,75 | 11,50 | 22,00 | 6,40 | 12,80 | 22,00 | 7,00 | 14,00 | 22,00 | 7,85 | 15,70 | 23,60 |

| 2,90 | 5,60 | 11,20 | 22,00 | 6,35 | 12,70 | 22,00 | 7,15 | 14,30 | 22,00 | 7,80 | 15,60 | 22,00 | 8,10 | 16,20 | 23,60 |

| 2,80 | 6,20 | 12,40 | 22,00 | 7,05 | 14,10 | 22,00 | 7,80 | 15,60 | 22,00 | 8,70 | 17,40 | 22,00 | | | |

| 2,70 | 6,85 | 13,70 | 22,00 | 7,80 | 15,60 | 22,00 | 8,50 | 17,00 | 22,00 | 9,60 | 19,20 | 22,00 | | | |

| 2,60 | 7,60 | 15,20 | 22,00 | 8,65 | 17,30 | 22,00 | 9,35 | 18,70 | 22,00 | 11,00 | 22,00 | 22,00 | | | |

| 2,50 | 8,55 | 17,10 | 22,00 | 9,50 | 19,00 | 22,00 | 11,00 | 22,00 | 22,00 | | | | | | |

| 2,40 | 9,65 | 19,30 | 22,00 | 11,00 | 22,00 | 22,00 | 11,00 | 22,00 | 22,00 | | | | | | |

| 2,30 | 11,00 | 22,00 | 22,00 | 11,00 | 22,00 | 22,00 | | | | | | | | | |

| 2,20 | 11,00 | 22,00 | 22,00 | 11,00 | 22,00 | 22,00 | | | | | | | | | |

| 2,10 | 11,00 | 22,00 | 22,00 | 11,00 | 22,00 | 22,00 | | | | | | | | | |

| 2,00 | 11,00 | 22,00 | 22,00 | | | | | | | | | | | | |

| 1,90 | 11,00 | 22,00 | 22,00 | | | | | | | | | | | | |

| 1,80 | 11,00 | 22,00 | 22,00 | | | | | | | | | | | | |

Type L2 push-pull props loads table

We - at GBM - manufacture 5 different types of L2 push-pull props models (PTS 3000 L2, PTS 3500 L2, PTS 4000 L2, PTS 4500 L2, PTS 5000 L2).

They are classified according to maximum extension and capacity. Below are their technical features.

| Ext. | PTS 3000 L2 | PTS 3500 L2 | PTS 4000 L2 | PTS 4500 L2 | PTS 5000 L2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compr. | Traction | Compr. | Traction | Compr. | Traction | Compr. | Traction | Compr. | Traction | ||||||

| (metri) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) |

| 5,00 | | | | | | | | | | | | | 2.42 | 4.84 | 36.70 |

| 4,90 | | | | | | | | | | | | | 2.55 | 5.11 | 36.70 |

| 4,80 | | | | | | | | | | | | | 2.70 | 5.41 | 36.70 |

| 4,70 | | | | | | | | | | | | | 2.87 | 5.73 | 36.70 |

| 4,60 | | | | | | | | | | | | | 3.05 | 6.09 | 36.70 |

| 4,50 | | | | | | | | | | 2.90 | 5.80 | 36.70 | 3.24 | 6.49 | 36.70 |

| 4,40 | | | | | | | | | | 3.08 | 6.15 | 36.70 | 3.46 | 6.93 | 36.70 |

| 4,30 | | | | | | | | | | 3.27 | 6.55 | 36.70 | 3.71 | 7.41 | 36.70 |

| 4,20 | | | | | | | | | | 3.49 | 6.98 | 36.70 | 3.98 | 7.96 | 36.70 |

| 4,10 | | | | | | | | | | 3.73 | 7.45 | 36.70 | 4.29 | 8.58 | 36.70 |

| 4,00 | | | | | | | 3.65 | 7.29 | 36.70 | 3.99 | 7.98 | 36.70 | 4.64 | 9.28 | 36.70 |

| 3,90 | | | | | | | 3.89 | 7.79 | 36.70 | 4.28 | 8.57 | 36.70 | 5.04 | 10.09 | 36.70 |

| 3,80 | | | | | | | 4.17 | 8.33 | 36.70 | 4.61 | 9.23 | 36.70 | 5.51 | 11.02 | 36.70 |

| 3,70 | | | | | | | 4.47 | 8.94 | 36.70 | 4.99 | 9.97 | 36.70 | 6.06 | 12.12 | 36.70 |

| 3,60 | | | | | | | 4.81 | 9.62 | 36.70 | 5.41 | 10.83 | 36.70 | 6.71 | 13.42 | 36.70 |

| 3,50 | | | | 4.70 | 9.39 | 36.70 | 5.19 | 10.38 | 36.70 | 5.91 | 11.81 | 36.70 | 7.47 | 14.95 | 36.70 |

| 3,40 | | | | 5.06 | 10.13 | 36.70 | 5.62 | 11.24 | 36.70 | 6.48 | 12.96 | 36.70 | 8.34 | 16.69 | 36.70 |

| 3,30 | | | | 5.47 | 10.95 | 36.70 | 6.11 | 12.22 | 36.70 | 7.16 | 14.32 | 36.70 | 9.21 | 18.43 | 36.70 |

| 3,20 | | | | 5.94 | 11.88 | 36.70 | 6.67 | 13.34 | 36.70 | 7.99 | 15.98 | 36.70 | 9.89 | 19.77 | 36.70 |

| 3,10 | | | | 6.47 | 12.93 | 36.70 | 7.32 | 14.65 | 36.70 | 9.01 | 18.02 | 36.70 | 10.33 | 20.65 | 36.70 |

| 3,00 | 6.51 | 13.03 | 36.70 | 7.07 | 14.14 | 36.70 | 8.10 | 16.20 | 36.70 | 10.30 | 20.60 | 36.70 | 10.65 | 21.31 | 36.70 |

| 2,90 | 7.12 | 14.25 | 36.70 | 7.76 | 15.53 | 36.70 | 9.03 | 18.07 | 36.70 | 11.94 | 23.88 | 36.70 | 10.96 | 21.91 | 36.70 |

| 2,80 | 7.83 | 15.65 | 36.70 | 8.57 | 17.15 | 36.70 | 10.19 | 20.39 | 36.70 | 13.66 | 27.33 | 36.70 | | | |

| 2,70 | 8.64 | 17.28 | 36.70 | 9.53 | 19.07 | 36.70 | 11.69 | 23.37 | 36.70 | 14.65 | 29.30 | 36.70 | | | |

| 2,60 | 9.59 | 19.19 | 36.70 | 10.69 | 21.38 | 36.70 | 13.71 | 27.42 | 36.70 | 15.25 | 30.50 | 36.70 | | | |

| 2,50 | 10.73 | 21.45 | 36.70 | 12.12 | 24.25 | 36.70 | 16.64 | 33.29 | 36.70 | | | | | | |

| 2,40 | 12.09 | 24.19 | 36.70 | 13.96 | 27.92 | 36.70 | 18.35 | 36.70 | 36.70 | | | | | | |

| 2,30 | 13.79 | 27.58 | 36.70 | 16.42 | 32.84 | 36.70 | | | | | | | | | |

| 2,20 | 15.95 | 31.90 | 36.70 | 18.35 | 36.70 | 36.70 | | | | | | | | | |

| 2,10 | 18.35 | 36.70 | 36.70 | 18.35 | 36.70 | 36.70 | | | | | | | | | |

| 2,00 | 18.35 | 36.70 | 36.70 | | | | | | | | | | | | |

| 1,90 | 18.35 | 36.70 | 36.70 | | | | | | | | | | | | |

| 1,80 | 18.35 | 36.70 | 36.70 | | | | | | | | | | | | |

Features of the “Type N push-pull” prop

In type N models, plumbing is carried out by means of a single ring nut which increases or reduces the extension of the prop depending on the rotation direction

The difference between the type N push-pull prop and the other classes lies in the type of verticality adjustment.

It is carried out by means of a single ring nut which increases or reduces the extension of the prop depending on the rotation direction.

The single ring nut can be slid in both directions by using two drilled details positioned in the cavities of the threaded pipes.

Below are the features of GBM’s “type N push-pull prop”:

- Extension adjustable between 1.80 and 5.00 m depending on the prop model, at 10 cm intervals by adjusting a spherical cast iron ring nut;

- Pulling guaranteed at 38.00 kN regardless of the use extension;

- Anti-shearing system: the greater length of the inner pipe with respect to that of the outer pipe enables guaranteeing an at least 10 cm difference between the two during the closing stage so as to avoid injury;

- Plates that can be articulated mounted on the two ends, so as to ensure the greatest adherence possible when fixing and mounting at multiple angles;

- Pipe protection: hot-dip galvanization in compliance with the UNI EN ISO 1461 standard, with a guaranteed minimum thickness of 55 microns;

- Inner pipe diameter 48 x 3.00 mm;

- Outer pipe diameter 60 x 2.50 mm;

Upon request:

- Sticker customised with the customer’s logo, bearing information on capacity and maximum extension;

Type N push-pull props loads table

We - at GBM - manufacture 5 different types of N push-pull props models (PTS 3000 N, PTS 3500 N, PTS 4000 N, PTS 4500 N, PTS 5000 N).

They are classified according to maximum extension and capacity. Below are their technical features.

| Ext. | PTS 3000 N |

PTS 3400 N |

PTS 4000 N |

PTS 4500 N |

PTS 5000 N |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compr. | Traz. | Compr. | Traz. | Compr. | Traz. | Compr. | Traz. | Compr. | Traz. | ||||||

| (metri) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) |

| 5,00 | | | | | | | | | | | | | 2.60 | 5.20 | 38.00 |

| 4,90 | | | | | | | | | | | | | 2.75 | 5.50 | 38.00 |

| 4,80 | | | | | | | | | | | | | 2.90 | 5.80 | 38.00 |

| 4,70 | | | | | | | | | | | | | 3.10 | 6.20 | 38.00 |

| 4,60 | | | | | | | | | | | | | 3.25 | 6.50 | 38.00 |

| 4,50 | | | | | | | | | | 3.20 | 6.40 | 38.00 | 3.55 | 7.10 | 38.00 |

| 4,40 | | | | | | | | | | 3.35 | 6.70 | 38.00 | 3.85 | 7.70 | 38.00 |

| 4,30 | | | | | | | | | | 3.60 | 7.20 | 38.00 | 4.05 | 8.10 | 38.00 |

| 4,20 | | | | | | | | | | 3.80 | 7.60 | 38.00 | 4.20 | 8.40 | 38.00 |

| 4,10 | | | | | | | | | | 4.05 | 8.10 | 38.00 | 4.55 | 9.10 | 38.00 |

| 4,00 | | | | | | | 4.05 | 8.10 | 38.00 | 4.35 | 8.70 | 38.00 | 4.90 | 9.80 | 38.00 |

| 3,90 | | | | | | | 4.35 | 8.70 | 38.00 | 4.65 | 9.30 | 38.00 | 5.30 | 10.60 | 38.00 |

| 3,80 | | | | | | | 4.65 | 9.30 | 38.00 | 5.05 | 10.10 | 38.00 | 5.80 | 11.60 | 38.00 |

| 3,70 | | | | | | | 5.00 | 10.00 | 38.00 | 5.45 | 10.90 | 38.00 | 6.40 | 12.80 | 38.00 |

| 3,60 | | | | | | | 5.40 | 10.80 | 38.00 | 5.90 | 11.80 | 38.00 | 7.10 | 14.20 | 38.00 |

| 3,50 | | | | | | | 5.85 | 11.70 | 38.00 | 6.45 | 12.90 | 38.00 | 8.00 | 16.00 | 38.00 |

| 3,40 | | | | 5.75 | 11.50 | 41.90 | 6.35 | 12.70 | 38.00 | 7.10 | 14.20 | 38.00 | 9.15 | 18.30 | 38.00 |

| 3,30 | | | | 6.25 | 12.50 | 41.90 | 6.95 | 13.90 | 38.00 | 7.85 | 15.70 | 38.00 | 10.70 | 21.40 | 38.00 |

| 3,20 | | | | 6.80 | 13.60 | 41.90 | 7.60 | 15.20 | 38.00 | 8.80 | 17.60 | 38.00 | 12.70 | 25.40 | 38.00 |

| 3,10 | | | | 7.40 | 14.80 | 41.90 | 8.45 | 16.90 | 38.00 | 10.05 | 20.10 | 38.00 | 14.00 | 28.00 | 38.00 |

| 3,00 | 7.00 | 14.00 | 41.90 | 8.10 | 16.20 | 41.90 | 9.45 | 18.90 | 38.00 | 11.70 | 23.40 | 38.00 | 14.50 | 29.00 | 38.00 |

| 2,90 | 7.65 | 15.30 | 41.90 | 8.95 | 17.90 | 41.90 | 10.70 | 21.40 | 38.00 | 14.05 | 28.10 | 38.00 | | | |

| 2,80 | 8.40 | 16.80 | 41.90 | 10.00 | 20.00 | 41.90 | 12.35 | 24.70 | 38.00 | 17.15 | 34.30 | 38.00 | | | |

| 2,70 | 9.25 | 18.50 | 41.90 | 11.25 | 22.50 | 41.90 | 14.60 | 29.20 | 38.00 | 18.45 | 36.90 | 38.00 | | | |

| 2,60 | 10.20 | 20.40 | 41.90 | 12.85 | 25.70 | 41.90 | 17.90 | 35.80 | 38.00 | 19.00 | 38.00 | 38.00 | | | |

| 2,50 | 11.35 | 22.70 | 41.90 | 14.95 | 29.90 | 41.90 | 19.00 | 38.00 | 38.00 | | | | | | |

| 2,40 | 12.75 | 25.50 | 41.90 | 17.85 | 35.70 | 41.90 | 19.00 | 38.00 | 38.00 | | | | | | |

| 2,30 | 14.50 | 29.00 | 41.90 | 19.50 | 39.00 | 41.90 | | | | | | | | | |

| 2,20 | 16.70 | 33.40 | 41.90 | 20.95 | 41.90 | 41.90 | | | | | | | | | |

| 2,10 | 19.05 | 38.10 | 41.90 | | | | | | | | | | | | |

| 2,00 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

| 1,90 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

| 1,80 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

Features of the “Type H push-pull” prop

In type H models, plumbing is carried out by means of two spherical cast iron ring nuts which increase or reduce the extension thereof. This model comes in two variants H1 and H2.

Type H1 push-pull

GBM - Type H1 push-pull.

Its distinctive features:

- pulling guaranteed at 38.00 kN

- inner pipe diameter 48 x 3.00 mm;

- outer pipe diameter 60 x 2.50 mm;

Type H2 push-pull

GBM - Type H2 push-pull

Its distinctive features:

- pulling guaranteed at 38.00/41.90 kN

- inner pipe diameter 63x 2.60 mm;

- outer pipe diameter 76 x 2.60 mm;

The difference between the type H push-pull prop and the other classes lies in the type of plumbing. It is carried out by means of two ring nuts which increase or reduce the extension of the prop.

We - at GBM manufacture two type H props: H1 (with smaller diameter) and H2 (with larger diameter). Both versions are characterised by:

- Extension adjustable between 1.80 and 5.40 m depending on the prop model, at 10 cm intervals by adjusting two steel ring nuts;

- Pulling guaranteed at 38.00 kN regardless of the use extension;

- Anti-shearing system: the greater length of the inner pipe with respect to that of the outer pipe enables guaranteeing an at least 10 cm difference between the two during the closing stage so as to avoid injury;

- Plates that can be articulated mounted on the two ends, so as to ensure the greatest adherence possible when fixing and mounting at multiple angles;

- Pipe protection: hot-dip galvanization in compliance with the UNI EN ISO 1461 standard, with a guaranteed minimum thickness of 55 microns;

- Inner pipe diameter 63x 2.60 mm;

- Outer pipe diameter 76 x 2.60 mm;

Upon request:

- Sticker customised with the customer’s logo, bearing information on capacity and maximum extension;

Type H1 push-pull props loads table

We - at GBM - manufacture 5 different types of H1 push-pull props models (PTS 3000 H1, PTS 3400 H1, PTS 4000 H1, PTS 4500 H1, PTS 5000 H1).

They are classified according to maximum extension and capacity. Below are their technical features.

| Extension | PTS 3000 H1 | PTS 3400 H1 | PTS 4000 H1 | PTS 4500 H1 | PTS 5000 H1 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compression | Traction | Compression | Traction | Compression | Traction | Compression | Traction | Compression | Traction | ||||||

| (metri) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) |

| 5,00 | | | | | | | | | | | | | 2.60 | 5.20 | 38.00 |

| 4,90 | | | | | | | | | | | | | 2.75 | 5.50 | 38.00 |

| 4,80 | | | | | | | | | | | | | 2.90 | 5.80 | 38.00 |

| 4,70 | | | | | | | | | | | | | 3.10 | 6.20 | 38.00 |

| 4,60 | | | | | | | | | | | | | 3.25 | 6.50 | 38.00 |

| 4,50 | | | | | | | | | | 3.20 | 6.40 | 38.00 | 3.55 | 7.10 | 38.00 |

| 4,40 | | | | | | | | | | 3.35 | 6.70 | 38.00 | 3.85 | 7.70 | 38.00 |

| 4,30 | | | | | | | | | | 3.60 | 7.20 | 38.00 | 4.05 | 8.10 | 38.00 |

| 4,20 | | | | | | | | | | 3.80 | 7.60 | 38.00 | 4.20 | 8.40 | 38.00 |

| 4,10 | | | | | | | | | | 4.05 | 8.10 | 38.00 | 4.55 | 9.10 | 38.00 |

| 4,00 | | | | | | | 4.05 | 8.10 | 38.00 | 4.35 | 8.70 | 38.00 | 4.90 | 9.80 | 38.00 |

| 3,90 | | | | | | | 4.35 | 8.70 | 38.00 | 4.65 | 9.30 | 38.00 | 5.30 | 10.60 | 38.00 |

| 3,80 | | | | | | | 4.65 | 9.30 | 38.00 | 5.05 | 10.10 | 38.00 | 5.80 | 11.60 | 38.00 |

| 3,70 | | | | | | | 5.00 | 10.00 | 38.00 | 5.45 | 10.90 | 38.00 | 6.40 | 12.80 | 38.00 |

| 3,60 | | | | | | | 5.40 | 10.80 | 38.00 | 5.90 | 11.80 | 38.00 | 7.10 | 14.20 | 38.00 |

| 3,50 | | | | | | | 5.85 | 11.70 | 38.00 | 6.45 | 12.90 | 38.00 | 8.00 | 16.00 | 38.00 |

| 3,40 | | | | 5.75 | 11.50 | 41.90 | 6.35 | 12.70 | 38.00 | 7.10 | 14.20 | 38.00 | 9.15 | 18.30 | 38.00 |

| 3,30 | | | | 6.25 | 12.50 | 41.90 | 6.95 | 13.90 | 38.00 | 7.85 | 15.70 | 38.00 | 10.70 | 21.40 | 38.00 |

| 3,20 | | | | 6.80 | 13.60 | 41.90 | 7.60 | 15.20 | 38.00 | 8.80 | 17.60 | 38.00 | 12.70 | 25.40 | 38.00 |

| 3,10 | | | | 7.40 | 14.80 | 41.90 | 8.45 | 16.90 | 38.00 | 10.05 | 20.10 | 38.00 | 14.00 | 28.00 | 38.00 |

| 3,00 | 7.00 | 14.00 | 41.90 | 8.10 | 16.20 | 41.90 | 9.45 | 18.90 | 38.00 | 11.70 | 23.40 | 38.00 | 14.50 | 29.00 | 38.00 |

| 2,90 | 7.65 | 15.30 | 41.90 | 8.95 | 17.90 | 41.90 | 10.70 | 21.40 | 38.00 | 14.05 | 28.10 | 38.00 | | | |

| 2,80 | 8.40 | 16.80 | 41.90 | 10.00 | 20.00 | 41.90 | 12.35 | 24.70 | 38.00 | 17.15 | 34.30 | 38.00 | | | |

| 2,70 | 9.25 | 18.50 | 41.90 | 11.25 | 22.50 | 41.90 | 14.60 | 29.20 | 38.00 | 18.45 | 36.90 | 38.00 | | | |

| 2,60 | 10.20 | 20.40 | 41.90 | 12.85 | 25.70 | 41.90 | 17.90 | 35.80 | 38.00 | 19.00 | 38.00 | 38.00 | | | |

| 2,50 | 11.35 | 22.70 | 41.90 | 14.95 | 29.90 | 41.90 | 19.00 | 38.00 | 38.00 | | | | | | |

| 2,40 | 12.75 | 25.50 | 41.90 | 17.85 | 35.70 | 41.90 | 19.00 | 38.00 | 38.00 | | | | | | |

| 2,30 | 14.50 | 29.00 | 41.90 | 19.50 | 39.00 | 41.90 | | | | | | | | | |

| 2,20 | 16.70 | 33.40 | 41.90 | 20.95 | 41.90 | 41.90 | | | | | | | | | |

| 2,10 | 19.05 | 38.10 | 41.90 | | | | | | | | | | | | |

| 2,00 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

| 1,90 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

| 1,80 | 20.95 | 41.90 | 41.90 | | | | | | | | | | | | |

Type H2 push-pull props loads table

We - at GBM - manufacture 3 different types of H2 push-pull props models (PTS 3000 H2, PTS 4000 H2, PTS 5000 H2).

They are classified according to maximum extension and capacity. Below are their technical features.

| Extension | PTS 3000 H2 | PTS 4000 H2 | PTS 5400 H2 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Compression | Traction | Compression | Traction | Compression | Traction | ||||

| (metri) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) | Ph (kN) | Pa (kN) | Pz (kN) |

| 5.40 | | | | | | | 4.05 | 8.10 | 38.00 |

| 5.30 | | | | | | | 4.35 | 8.70 | 38.00 |

| 5.20 | | | | | | | 4.65 | 9.30 | 38.00 |

| 5.10 | | | | | | | 5.00 | 10.00 | 38.00 |

| 5.00 | | | | | | | 5.40 | 10.80 | 38.00 |

| 4,90 | | | | | | | 5.85 | 11.70 | 38.00 |

| 4,80 | | | | | | | 6.35 | 12.70 | 38.00 |

| 4,70 | | | | | | | 6.95 | 13.90 | 38.00 |

| 4,60 | | | | | | | 7.60 | 15.20 | 38.00 |

| 4,50 | | | | | | | 8.45 | 16.90 | 38.00 |

| 4,40 | | | | | | | 9.45 | 18.90 | 38.00 |

| 4,30 | | | | | | | 10.70 | 21.40 | 38.00 |

| 4,20 | | | | | | | 12.35 | 24.70 | 38.00 |

| 4,10 | | | | | | | 14.60 | 29.20 | 38.00 |

| 4,00 | | | | 5.75 | 11.50 | 41.90 | 17.90 | 35.80 | 38.00 |

| 3,90 | | | | 6.25 | 12.50 | 41.90 | 19.00 | 38.00 | 38.00 |

| 3,80 | | | | 6.80 | 13.60 | 41.90 | 19.00 | 38.00 | 38.00 |

| 3,70 | | | | 7.40 | 14.80 | 41.90 | | | |

| 3,60 | | | | 8.10 | 16.20 | 41.90 | | | |

| 3,50 | | | | 8.95 | 17.90 | 41.90 | | | |

| 3,40 | | | | 10.00 | 20.00 | 41.90 | | | |

| 3,30 | | | | 11.25 | 22.50 | 41.90 | | | |

| 3,20 | | | | 12.85 | 25.70 | 41.90 | | | |

| 3,10 | | | | 14.95 | 29.90 | 41.90 | | | |

| 3,00 | 7.00 | 14.00 | 41.90 | 17.85 | 35.70 | 41.90 | | | |

| 2,90 | 7.65 | 15.30 | 41.90 | 19.50 | 39.00 | 41.90 | | | |

| 2,80 | 8.40 | 16.80 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,70 | 9.25 | 18.50 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,60 | 10.20 | 20.40 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,50 | 11.35 | 22.70 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,40 | 12.75 | 25.50 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,30 | 14.50 | 29.00 | 41.90 | 20.95 | 41.90 | 41.90 | | | |

| 2,20 | 16.70 | 33.40 | 41.90 | | | | | | |

| 2,10 | 19.05 | 38.10 | 41.90 | | | | | | |

| 2,00 | 20.95 | 41.90 | 41.90 | | | | | | |

| 1,90 | 20.95 | 41.90 | 41.90 | | | | | | |

| 1,80 | 20.95 | 41.90 | 41.90 | | | | | | |

Сравнительная таблица

| | PTS 3000 L1 | PTS 3500 L1 | PTS 4000 L1 | PTS 4500 L1 | PTS 5000 L1 | PTS 3000 L2 | PTS 3500 L2 | PTS 4000 L2 | PTS 4500 L2 | PTS 5000 L2 | PTS 3000 N | PTS 3500 N | PTS 4000 N | PTS 4500 N | PTS 5000 N | PTS 3000 H1 | PTS 3500 H1 | PTS 4000 H1 | PTS 4500 H1 | PTS 5000 H1 | PTS 3000 H2 | PTS 4000 H2 | PTS 5400 H2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAX EXT. (m) | 3,05 | 3,55 | 4,05 | 4,55 | 5,05 | 3,05 | 3,55 | 4,05 | 4,55 | 5,05 | 3,05 | 3,45 | 4,05 | 4,55 | 5,05 | 3,05 | 3,45 | 4,05 | 4,55 | 5,05 | 3,05 | 4,05 | 5,45 |

| MIN EXTENSION (m) | 1,75 | 2,05 | 2,35 | 2,55 | 2,85 | 1,75 | 2,05 | 2,35 | 2,55 | 2,85 | 1,80 | 2,20 | 2,40 | 2,60 | 2,90 | 1,80 | 2,20 | 2,40 | 2,60 | 2,90 | 1,75 | 2,30 | 3,10 |

| Ø INNER TUBE (mm) | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 63,50 | 63,50 | 63,50 |

| INNER TUBE THICKNESS (mm) | 1,80 | 1,80 | 1,80 | 1,80 | 1,80 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 3,00 | 2,60 | 2,60 | 2,60 |

| Ø OUTER TUBE (mm) | 56,00 | 56,00 | 56,00 | 56,00 | 56,00 | 57,00 | 57,00 | 57,00 | 57,00 | 57,00 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 76,10 | 76,10 | 76,10 |

| OUTER TUBE THICKNESS (mm) | 1,65 | 1,65 | 1,65 | 1,65 | 1,65 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,50 | 2,60 | 2,60 | 2,60 |

| PLATES | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | No | No | No |

| WEIGHT (Kg) | 9,40 | 10,50 | 11,50 | 12,60 | 13,80 | 13,40 | 15,10 | 16,60 | 18,30 | 20,20 | 15,95 | 18,30 | 20,90 | 22,80 | 25,15 | 16,50 | 18,95 | 21,55 | 23,45 | 25,80 | 18,35 | 22,55 | 30,30 |

GBM props catalogue

Would you like to view the full GBM props catalogue?

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

Бланк для связи: информация, цены, расчет стоимости

Хотите узнать больше о продуктах GBM? Мы ответим на любой ваш запрос!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)