Formwork panels

Indispensable for any construction site.

GBM’s formwork panels consist of three coated layers of wood.

About GBM's formwork panels

GBM formwork 3ply panels are built with three layers of wood obtained from fir and spruce trees grown in sustainable forests.

The melamine resin they are coated with confers resistance and uniformity to the surface of the panels thus making them suitable for use in any construction site.

Often used in the construction industry, they stand out for quality and durability.

Technical features

Below are the features of GBM shuttering panels

- Wood type: spruce and red fir

- Wood humidity: 12% +/-2%

- Thickness: 21mm; 27mm

- Weight:

- 21 mm = 10 kg/m2;

- 27 mm = 12,3 kg/m2;

- Protection surface: highly resistant melamine resin coating

- Standard packaging:

- 21 mm: 100 pcs per package

- 27 mm: 80 pcs per package

GBM formwork panels technical data

| Thickness mm | 27 | 27, optional | 21, optional |

| Width mm | 500 | 200, 250, 300, 350, 400, 450 | 500 |

| Length mm | 1000, 1500, 2000, 2500, 3000 | 3000 | 1000, 1500, 2000, 2500, (3000) |

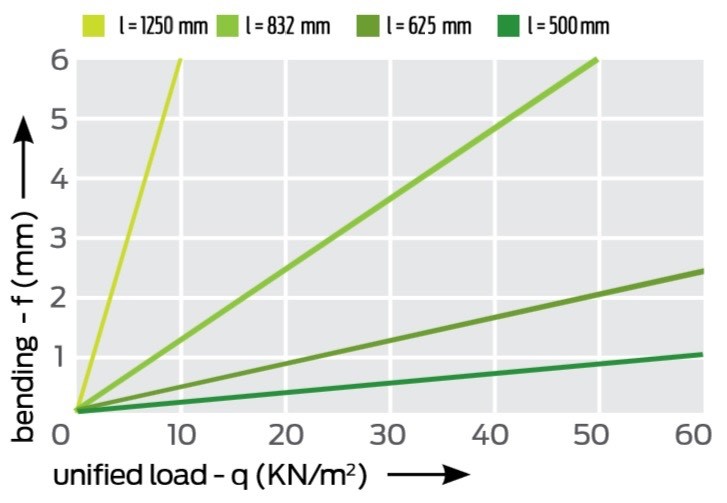

The diagram shows how the panel reacts upon loading, considering the interval spaces between one support element and the other.

Q stands for uniform load (in kN/ m2 unit).

I stands for interval space between the support elements.

f is the folding calculated in mm.

Our worksites

Here are some examples of our construction sites. Click here to visit the complete gallery

Technical data sheet

As a tool, the GBM formwork panels technical data sheet is useful for worksite operators. The technical data sheet informs the operator about the main features of the panels.

Download the GBM formwork panels technical data sheet in pdf format (1 MB)

.

Download the GBM formwork panels' assembly manual in pdf format (3.7 MB)

.

GBM's beams and panels catalogue

Would you like to see the full catalogue of GBM's beams and panels?

Download the full catalogue in pdf format (3 MB).

Or go straight to the online version.

Content of the catalogue? General information and technical features: type of wood, weight, dimensions (they come in various standard lengths), certificates etc.

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

Бланк для связи: информация, цены, расчет стоимости

Хотите узнать больше о продуктах GBM? Мы ответим на любой ваш запрос!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)