DIN EN 1065 EURO heavy duty props

GBM heavy duty shoring systems. They bear more than 30kN.

Made in Italy. Certified in Germany. Used worldwide.

In this page:

- About “DIN EN 1065” prop,

- Technical features,

- DIN EN 1065 class B props loads table,

- DIN EN 1065 class D props loads table,

- DIN EN 1065 class E props loads table,

- Comparative table of DIN props,

- Our worksites,

- Videotutorial,

- DIN Certificates,

- DIN EN 1065 props use and maintenance instructions booklet,

- Pdf catalogue,

- GBM shoring props: data sheet

About the “DIN EN 1065” props

GBM DIN EN 1065 GBM props are heavy duty props. Designed to bear heavy loads - more than 30kN - they are at the core of GBM production.

Thanks to the certificate issued by the strict German technical institute "Materialprüfungsanstalt Universität Stuttgart", they fully comply with the UNI EN 1065:1999 European standard.

This standard set the toughest requirements worldwide as regards materials, design requirements and protection measures against corrosion.

The handle of the prop always features a marking bearing the following:

- The standard subject of compliance;

- Year of manufacture;

- Manufacturer Identification Code (G stands for GBM).

DIN EN 1065 heavy duty props come in the following versions:

- Coated;

- Electrolytically galvanized;

- Hot dip galvanized.

This type of prop can be customised using branded stickers upon request.

These products are compatible with most accessories of other formworks and floors.

GBM DIN EN 1065 props come in three models, depending on the guaranteed maximum capacity at the maximum extensions:

Do you want to download the Dimensional table for DIN EN 1065 GBM props in PDF format?

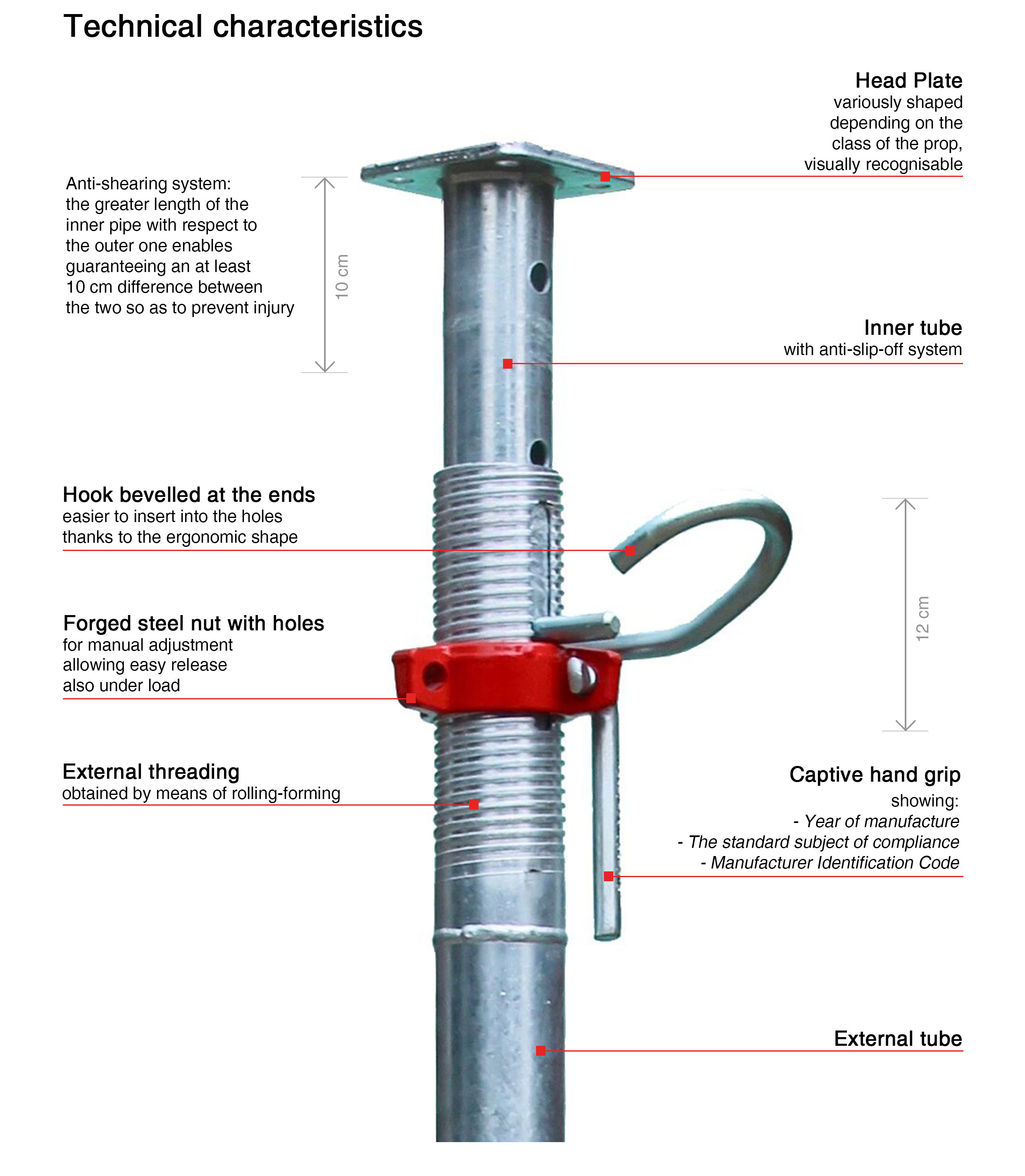

Technical features of “DIN EN 1065” prop

Below are the features of GBM “DIN EN 1065” EURO prop:

- variously shaped plates depending on the class of the prop, so as to make it immediately recognisable visually;

- forged steel adjustment ring nut with two supplementary holes, suitable for millimetric adjustment;

- hook bevelled at the ends: easier to insert into the holes thanks to the ergonomic shape;

- anti-shearing system: the greater length of the inner pipe with respect to the outer one enables guaranteeing an at least 10 cm difference between the two so as to prevent injury;

- outer threading obtained by means of rolling-forming, hence guaranteeing the wholeness of the material without removing any material;

- inner holes obtained using machines capable of perfectly machining them or by means of a milling system which obtains turnings on the surface of the pipe: both ways enable guaranteeing the complete absence of burrs near the holes;

- inner pipe anti-slip-off system, so as to prevent the pipe from inadvertently slipping off thus guaranteeing wholeness and safety when laying down and displacing at the worksite;

- three types of surface protections, obtained through the process of:

- dip coating;

- passivated electrolytic galvanising (tropicalisation), with guaranteed minimum thickness of 10 microns;

- hot-dip galvanization, with guaranteed minimum thickness of 50 microns;

Upon request:

- sticker customised with customer's logo, bearing information on capacity and maximum extension;

- quick release system, an accessory that guarantees release of the prop under the load by just hitting with the hammer to quicken and simplify the release procedure as well as reduce the operator's effort;

- tripod stand capable of supporting the prop when laying on site and when laying the floor;

- three different types of fork for supporting the floor, depending on the manufacturer’s needs:

- head stop fork (simple),

- 4-way head,

- fork referred to as "drop head".

Beware: the capacities indicated in the table always refer to the capacity of the single post shore. Higher capacities can be achieved by binding, gate-like systems or pipe-coupling systems. The gate-like system is a temporary structure suitable for creating a loading tower. Binding the props in fours enables maximising the capacity. The pipe-coupling system provides for a pipe above and beneath with couplings; it is the same figure of the gate, which is more economic though less quick.

DIN EN 1065 class B props loads table

We - at GBM - manufacture three different models of the DIN EN 1065 class B props (B 30, B 35, B 40).

These are classified according to maximum extension (this model is capable of covering extensions between 1.82 m and 4.00 m) and capacity (higher with closed configuration).

Below are the technical features of each one of them.

Dimensions table

| B 30 | B 35 | B 40 | ||

|---|---|---|---|---|

| Maximum extension | cm | 300 | 350 | 400 |

| Minimum extension | cm | 182 | 207 | 234 |

| Inner diameter | mm | 48,30 | 48,30 | 48,30 |

| Outer diameter | mm | 60,30 | 60,30 | 60,30 |

| Weight | Kg | 14,50 | 15,80 | 17,90 |

Extension (meters) |

B 30 1,82 - 3,00 m (kN) |

B 35 2,07 - 3,50 m (kN) |

B 40 2,34 - 4,00 m (kN) |

|---|---|---|---|

| 4,0 | 11,6 | ||

| 3,9 | 12,6 | ||

| 3,8 | 13,1 | ||

| 3,7 | 13,9 | ||

| 3,6 | 14,8 | ||

| 3,5 | 15,8 | 15,5 | |

| 3,4 | 17,0 | 16,2 | |

| 3,3 | 18,1 | 17,1 | |

| 3,2 | 18,3 | 18,3 | |

| 3,1 | 20,2 | 19,4 | |

| 3,0 | 21,1 | 20,8 | 20,1 |

| 2,9 | 23,1 | 21,0 | 21,3 |

| 2,8 | 24,8 | 21,1 | 22,8 |

| 2,7 | 27,0 | 21,4 | 25,9 |

| 2,6 | 28,9 | 22,0 | 30,0 |

| 2,5 | 30,6 | 23,3 | 30,0 |

| 2,4 | 32,1 | 25,1 | 30,0 |

| 2,3 | 34,0 | 28,8 | 30,0 |

| 2,2 | 36,8 | 30,0 | |

| 2,1 | 39,0 | 30,0 | |

| 2,0 | 39,0 | 30,0 | |

| 1,9 | 39,0 | ||

| 1,8 | 39,0 |

DIN EN 1065 class D props loads table

We - at GBM manufacture eight different models of DIN EN 1065 class D props (D25 ECO, D30 ECO, D35 ECO, D30, D35, D40, D45, D55). In some sizes, these products also come in the “eco” version, available at a lower price, but still capable of maintaining the guaranteed 20kn capacity at the maximum extensions.

The eight models are classified according to the maximum extension (comprised between 1.80 m and 5.50 m) and capacity.

Below are the technical features of each one of them.

Download the whole DIN EN class D loads table

Dimensions table

| D 25 ECO | D 30 ECO | D 35 ECO | D 30 | D 35 | D 40 | D 45 | D 55 | ||

|---|---|---|---|---|---|---|---|---|---|

| Maximum extension | cm | 250 | 300 | 350 | 300 | 350 | 400 | 450 | 550 |

| Minimum extension | cm | 146 | 182 | 207 | 173 | 198 | 225 | 250 | 303 |

| Inner diameter | mm | 48,30 | 48,30 | 48,30 | 63,50 | 63,50 | 63,50 | 63,50 | 76,10 |

| Outer diameter | mm | 60,30 | 60,30 | 60,30 | 76,10 | 76,10 | 76,10 | 76,10 | 88,90 |

| Weight | Kg | 13,00 | 15,90 | 17,60 | 17,80 | 19,70 | 22,10 | 27,50 | 35,00 |

Extension |

D 25 ECO 1,50 - 2,50 m |

D 30 ECO 1,82 - 3,00 m |

D 35 ECO 2,07 - 3,50 m |

D 30 1,73 - 3,00 m |

D 35 1,98 - 3,50 m |

D 40 2,25 - 4,00 m |

D 45 2,50 - 4,50 m |

D 55 3,03 - 5,50 m |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Up | Down | Up | Down | Up | Down | Up |

Down | Up | Down | Up | Down | Up | Down | Up | Down | |

| (meters) | (kN) | |||||||||||||||

| 5,5 | 21,8 | 24,0 | ||||||||||||||

| 5,4 | 22,9 | 25,2 | ||||||||||||||

| 5,3 | 23,9 | 26,3 | ||||||||||||||

| 5,2 | 25,1 | 27,6 | ||||||||||||||

| 5,1 | 26,6 | 29,3 | ||||||||||||||

| 5,0 | 27,5 | 30,3 | ||||||||||||||

| 4,9 | 29,3 | 32,2 | ||||||||||||||

| 4,8 | 30,6 | 33,7 | ||||||||||||||

| 4,7 | 32,6 | 35,9 | ||||||||||||||

| 4,6 | 33,7 | 37,1 | ||||||||||||||

| 4,5 | 20,6 | 22,9 | 35,6 | 39,0 | ||||||||||||

| 4,4 | 21,8 | 24,3 | 37,6 | 39,0 | ||||||||||||

| 4,3 | 23,0 | 25,7 | 39,0 | 39,0 | ||||||||||||

| 4,2 | 24,4 | 27,2 | 39,0 | 39,0 | ||||||||||||

| 4,1 | 25,8 | 28,9 | 39,0 | 39,0 | ||||||||||||

| 4,0 | 21,8 | 25,1 | 27,3 | 30,5 | 39,0 | 39,0 | ||||||||||

| 3,9 | 22,6 | 26,0 | 28,9 | 32,4 | 39,0 | 39,0 | ||||||||||

| 3,8 | 24,5 | 28,2 | 30,7 | 34,3 | 39,0 | 39,0 | ||||||||||

| 3,7 | 26,5 | 30,5 | 32,7 | 36,3 | 39,0 | 39,0 | ||||||||||

| 3,6 | 27,7 | 31,9 | 34,7 | 36,7 | 39,0 | 39,0 | ||||||||||

| 3,5 | 20,60 | 24,10 | 23,9 | 28,7 | 29,6 | 34,0 | 35,0 | 36,7 | 39,0 | 39,0 | ||||||

| 3,4 | 20,90 | 24,80 | 26,0 | 31,2 | 31,9 | 36,7 | 35,0 | 36,7 | 39,0 | 39,0 | ||||||

| 3,3 | 21,30 | 25,40 | 28,1 | 33,7 | 33,8 | 38,9 | 35,0 | 36,7 | 39,0 | 39,0 | ||||||

| 3,2 | 21,70 | 26,00 | 30,3 | 36,4 | 35,2 | 39,0 | 35,0 | 36,7 | 39,0 | 39,0 | ||||||

| 3,1 | 22,20 | 26,70 | 32,1 | 38,5 | 36,4 | 39,0 | 35,0 | 36,7 | 39,0 | 39,0 | ||||||

| 3,0 | 21,1 | 25,3 | 22,70 | 27,40 | 29,3 | 35,2 | 33,3 | 39,0 | 38,3 | 39,0 | 35,0 | 36,7 | ||||

| 2,9 | 23,1 | 27,7 | 23,30 | 28,30 | 30,7 | 36,8 | 34,2 | 39,0 | 39,0 | 39,0 | 35,0 | 36,7 | ||||

| 2,8 | 24,8 | 29,8 | 24,00 | 30,00 | 31,6 | 37,9 | 34,8 | 39,0 | 39,0 | 39,0 | 35,0 | 36,7 | ||||

| 2,7 | 27,0 | 32,4 | 24,60 | 31,10 | 32,2 | 38,6 | 35,4 | 39,0 | 39,0 | 39,0 | 35,0 | 36,7 | ||||

| 2,6 | 28,9 | 34,7 | 25,30 | 32,30 | 32,9 | 39,0 | 36,9 | 39,0 | 39,0 | 39,0 | 35,0 | 36,7 | ||||

| 2,5 | 20,2 | 24,8 | 30,6 | 36,7 | 26,00 | 34,00 | 33,6 | 39,0 | 38,7 | 39,0 | 39,0 | 39,0 | 35,0 | 36,7 | ||

| 2,4 | 21,3 | 27,2 | 32,1 | 38,5 | 26,70 | 35,20 | 34,6 | 39,0 | 39,0 | 39,0 | 39,0 | 39,0 | ||||

| 2,3 | 22,5 | 29,5 | 34,0 | 39,0 | 27,50 | 37,50 | 35,7 | 39,0 | 39,0 | 39,0 | 39,0 | 39,0 | ||||

| 2,2 | 23,3 | 31,9 | 36,8 | 39,0 | 28,50 | 39,00 | 37,2 | 39,0 | 39,0 | 39,0 | ||||||

| 2,1 | 24,0 | 34,3 | 39,0 | 39,0 | 30,00 | 39,00 | 38,8 | 39,0 | 39,0 | 39,0 | ||||||

| 2,0 | 24,6 | 36,7 | 39,0 | 39,0 | 39,0 | 39,0 | 39,0 | 39,0 | ||||||||

| 1,9 | 25,8 | 36,7 | 39,0 | 39,0 | 39,0 | 39,0 | ||||||||||

| 1,8 | 26,9 | 36,7 | 39,0 | 39,0 | 39,0 | 39,0 | ||||||||||

| 1,7 | 28,4 | 36,7 | ||||||||||||||

| 1,6 | 30,1 | 36,7 | ||||||||||||||

| 1,5 | 31,8 | 36,7 | ||||||||||||||

DIN EN 1065 class E props loads table

We - at GBM - manufacture three different models of the DIN EN 1065 class E props (E 30, E 35, E 40). They are classified according to maximum extension and capacity. Below are the technical features of each one of them.

Dimensions table

| E 30 | E 35 | E 40 | ||

|---|---|---|---|---|

| Maximum extension | cm | 300 | 350 | 400 |

| Minimum extension | cm | 173 | 198 | 225 |

| Inner diameter | mm | 63,50 | 63,50 | 76,10 |

| Outer diameter | mm | 76,10 | 76,10 | 88,90 |

| Weight | Kg | 17,50 | 23,80 | 26,00 |

| Extension | E 30 1,73 - 3,00 m |

E 35 1,98 - 3,50 m |

E 40 2,25 - 4,00 m |

|||

|---|---|---|---|---|---|---|

| Up | Down | Up | Down | Up |

Down | |

| (meters) | (kN) | |||||

| 4,0 | 33,2 | 36,5 | ||||

| 3,9 | 36,8 | 40,5 | ||||

| 3,8 | 39,0 | 41,0 | ||||

| 3,7 | 41,0 | 41,0 | ||||

| 3,6 | 41,0 | 41,0 | ||||

| 3,5 | 32,0 | 33,6 | 41,0 | 41,0 | ||

| 3,4 | 35,3 | 37,1 | 41,0 | 41,0 | ||

| 3,3 | 37,7 | 39,6 | 41,0 | 41,0 | ||

| 3,2 | 40,0 | 41,0 | 41,0 | 41,0 | ||

| 3,1 | 41,0 | 41,0 | 41,0 | 41,0 | ||

| 3,0 | 32,4 | 35,6 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,9 | 35,8 | 39,4 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,8 | 36,4 | 40,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,7 | 37,3 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,6 | 38,8 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,5 | 39,7 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,4 | 40,0 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,3 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 | 41,0 |

| 2,2 | 41,0 | 41,0 | 41,0 | 41,0 | ||

| 2,1 | 41,0 | 41,0 | 41,0 | 41,0 | ||

| 2,0 | 41,0 | 41,0 | 41,0 | 41,0 | ||

| 1,9 | 41,0 | 41,0 | ||||

| 1,8 | 41,0 | 41,0 | ||||

Comparative table of DIN props

| | B 30 | B 35 | B 40 | D 25 ECO | D 30 ECO | D 35 ECO | D 30 | D 35 | D 40 | D 45 | D 55 | E 30 | E 35 | E 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MAX EXT. (m) | 3,00 | 3,50 | 4,00 | 2,50 | 3,00 | 3,50 | 3,00 | 3,50 | 4,00 | 4,50 | 5,50 | 3,00 | 3,50 | 4,00 |

| MIN EXT. (m) | 1,82 | 2,07 | 2,34 | 1,46 | 1,82 | 2,07 | 1,73 | 1,98 | 2,25 | 2,50 | 3,03 | 1,73 | 1,98 | 2,25 |

| Ø INNER TUBE (mm) | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 48,30 | 63,50 | 63,50 | 63,50 | 63,50 | 76,10 | 63,50 | 63,50 | 76,10 |

| Ø OUTER TUBE (mm) | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 60,30 | 76,10 | 76,10 | 76,10 | 76,10 | 88,90 | 76,10 | 76,10 | 88,90 |

| Weight (Kg) | 14,50 | 15,80 | 17,90 | 13,00 | 15,90 | 17,60 | 17,80 | 19,70 | 22,10 | 27,50 | 35,00 | 17,50 | 23,80 | 26,00 |

Our worksites

Here are some examples of our construction sites. Click here to visit the complete gallery

Videotutorial

DIN certificate

The DIN certificate for GBM Building Equipment DIN EN 1065 telescopic props is a quality assurance issued by a prestigious University Institute. The certificate guarantees perfect functionality of the telescopic prop under load.

Download the DIN certificate for GBM DIN EN 1065 EURO props in pdf format (1 MB)

.

DIN EN 1065 props assembly, use and maintenance instructions booklet

GBM DIN EN 1065 telescopic props assembly, use and maintenance instructions booklet is a crucial instrument for the worksite operator. Besides instructing the operator on assembly, use and maintenance, the instructions booklet also offers information on perfect functionality, depending on the model and extension, of the telescopic prop under load.

Download GBM DIN EN 1065 props assembly, use and maintenance instructions booklet in pdf (2.3 MB) metric system format,

.

Download GBM DIN EN 1065 props assembly, use and maintenance instructions booklet in pdf (2.3 MB) imperial system format

.

GBM props catalogue

Would you like to view the full GBM props catalogue?

GBM Shoring Props: Data Sheet

GBM shoring prop specifications, data sheet & capacity tables: maximum extension, minimum extension, inner tube, outer tube, weight, compression... If you want to know it all, just...

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)