GBM post shores

We - at GBM - have been one of the largest manufacturers of building post shores in Italy for more than 60 years.

Discover technical data on length, diameter and capacity for all types and choose the post shore that best suits your needs.

Or get a request an offer right away in just a few seconds.

Types of post shores

We - at GBM - have been manufacturing post shores suitable for all worksite needs for more than 60 years.

Below are our seven types of shoring systems.

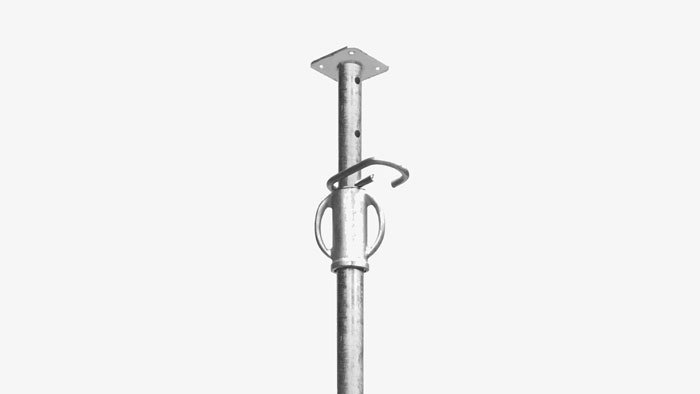

“Italia” light post shores

Light post shores: historical economic and versatile models made in Italy. Made of steel, they are dip-coated (red).

French post shores

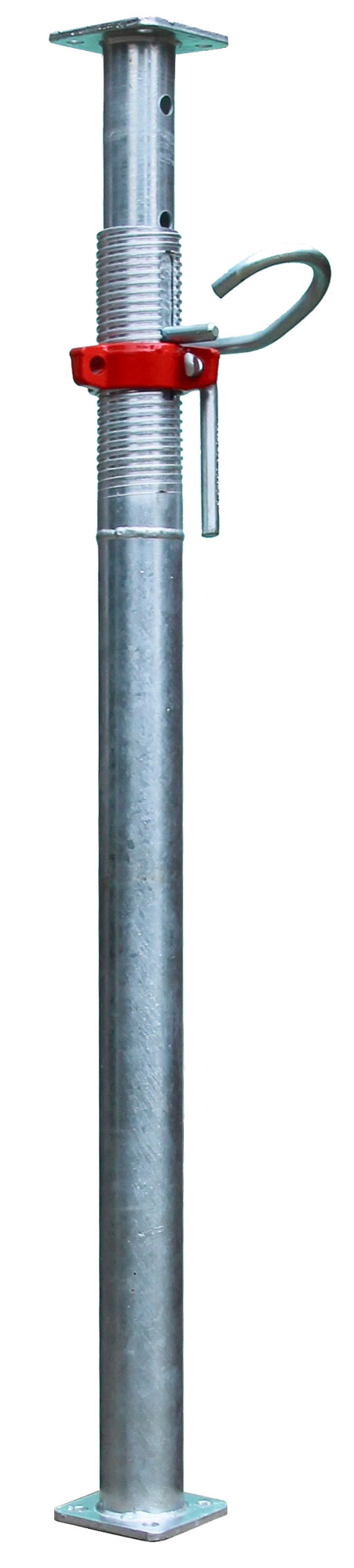

Post shores of french type, the most used in the French-speaking countries. Available in painted and galvanized version.

DIN EN 1065 EURO post shores

High capacity post shores, designed to bear more than 30kN. Made in Italy but DIN EN 1065-approved with certificate issued in Germany.

Fork head post shores

Post shores made with fork head already welded to support the beam in the shoring system. Manufactured according to the customer's ABOMA.

Push-pull post shores

Push-pull post shores: they operate pulling and pushing to hold the formworks in position when laying at the site.

Aluminium post shores

Alu post shores: besides being the lightest, reach higher heights and greater capacity as compared to equivalent steel post shores.

ANSI SSFI SH300 post shores

GBM heavy duty shoring systems, made to satisfy the North American ANSI standard.

They bear more than 16500 lbs.

Shoring towers

These are modular structures capable of reaching 12 metres high. Ideal for working off the ground, guaranteeing safe, quick and simple operating conditions.

GBM post shores catalogue

Would you like to view the full GBM post shores catalogue?

GBM Post Shores: Data Sheet

GBM post shore specifications, data sheet & capacity tables: maximum extension, minimum extension, inner tube, outer tube, weight, compression... If you want to know it all, just...

Manufacturing building post shores.

GBM: made in Italy, used worldwide.

We - at GBM - have been designing, manufacturing and selling post shores for more than 60 years.

This is why construction companies across the world opt for our products.

Post shores are the starting point in every multi-storey building construction. They are generally classified into: light post shores, DIN EN 1065 post shores, push-pull post shores, forked post shores, aluminium post shores and loading towers.

Besides helping you save materials and time, these post shores are a safe bet to achieve your results at the worksite.

We - at GBM - have been in the post shores manufacturing industry for more than 60 years.

Ever groundbreakers, since back when we were just small-scale manufactures up to today when we utilise the most advanced metal and finished product machining techniques, ever striving to achieve top-notch production.

Our post shores meet all quality standards required by the most demanding standards worldwide, throughout the entire manufacturing process.

Furthermore they are compatible with the most famous and widespread formwork systems, such as Dokadek 30, Dokaflex, Skydeck, Framax, Rasto-Takko, and many more.

Here is why our production process is unique:

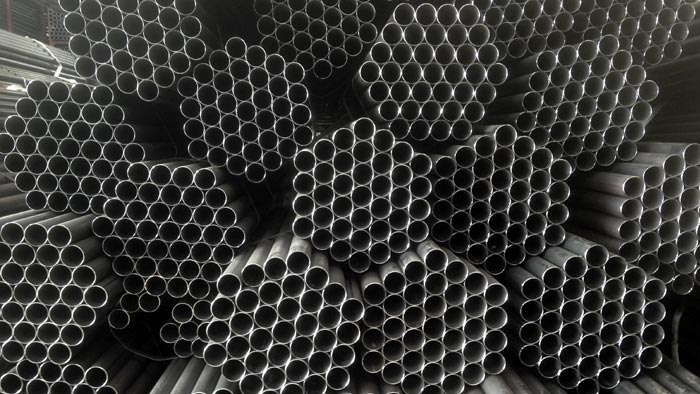

- our products are made of quality raw materials, procured from painstakingly selected suppliers;

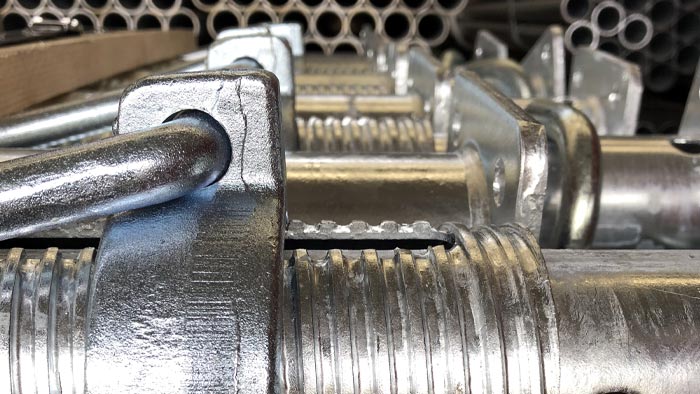

- we care about their durability and resistance over time and against harsh conditions, coating them with utmost protection (hot-dip galvanization in compliance with the UNI EN ISO 1461 standard)

- we meet safety conditions by providing anti-shearing and anti-slip-off systems.

However, manufacturing top-quality and supreme durability post shores is just the starting point to us: our experience alongside those working on the ground in any international market, has led us to diversifying our production into six different types of products striving towards meeting any demand.

Post shores manufacturing steps

Post shores machining steps: we manufacture our products with utmost care, in compliance with the toughest standards in Italy and in Europe.

GBM products are sold all over the world. Thus, each and every product must comply with safety and reliability standards always exceeding the standards required in the country of use.

Setting up a safe construction site requires compliance with strict standards. Right from the choice of materials used for setting up the worksite. This is why we - at GBM - make our products in compliance with strict quality standards: to guarantee safety and reliability for our customers. And for the customers of our customers.

Basically, here are the steps for manufacturing a certified GBM post shore.

For further details on GBM, certifications on our products and on our "post shores made in Italy", please contact us.

PROJECT — It all starts with our customer's needs. Whether you are a dealer in building materials on the other corner of the globe, or a major constructor striving to complete a large project, or a small-scale construction company, the first step always lies in identifying which products you actually need.

RAW MATERIAL — Our technical department will then select the raw material depending on the required type of post shore, by verifying the quality of the steel.

CUTTING — Steel pipes (both external and internal) are then cut to size with a +/-1 mm tolerance. Cutting is done using automatic cutting machines: a bundle of pipes is placed on the loader which selects one pipe at a time. It is then loaded on a positioning device and cut precisely at the desired height. Lastly, the pipe is unloaded into a container for the subsequent step.

DRILLING — Then there follows the drilling step, which is carried out depending on the type of pipe. Due to the new technologies, the drilling is quick, precise and burr-free.

WELDING — External pipes proceed to the welding step, where - suitably positioned - they are assembled with the base plate (previously forged by 250-ton press machines) and the end is threaded (obtained through a rolling-forming process, which reinforces its structure). Once drilled, the internal pipes undergo the same welding process but concerning the plate only.

COATING AND GALVANISING — Once welded, the post shores can be: dip coated, cold-dip galvanised (electrolytically), for a more durable protection with respect to dip coating and for better aesthetic quality or hot dip galvanised for a basically permanent protection, suitable for all environments and withstanding external atmospheric agents.

FINISH — Depending on the product, next come the completion steps including: mounting an outer sleeve on the covered threading or a forged steel ring nut on which the product identification code is stamped; marking the plates with the customer’s identification code.

CUSTOMISATION — Customised products are available upon request: for example with a ring nut bearing the customer's colours, or the customisation of the post shore using stickers bearing the customer's logo;

CAPACITY TEST — We perform in-house tests (capacity tests) on randomly collected samples.

PACKAGING AND SHIPMENT — Once through with machining, we proceed to the packaging step. Packages usually come with 50 pieces, strapped. The material is then loaded into a truck or container and shipped.

News

GBM's shipbuilding scaffoldings

Post shores required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)