Wooden panels cleaner "Puli-Pan"

GBM wooden panels cleaner allows you to easily clean your 3ply panels for formworks.

In this page:

Wooden panels cleaner "Puli-Pan"

GBM wooden panels cleaner allows you to easily clean your 3ply panels for formworks.

Cleans the four sides of panels simultaneously applying the release agent.

Advancement speed about 6 meters per minute.

Equipped with lifting screws, a removable handle, wheels and safety device.

On request, driving roller gears special to clean thickness from 21 up to 27 mm.

Technical features

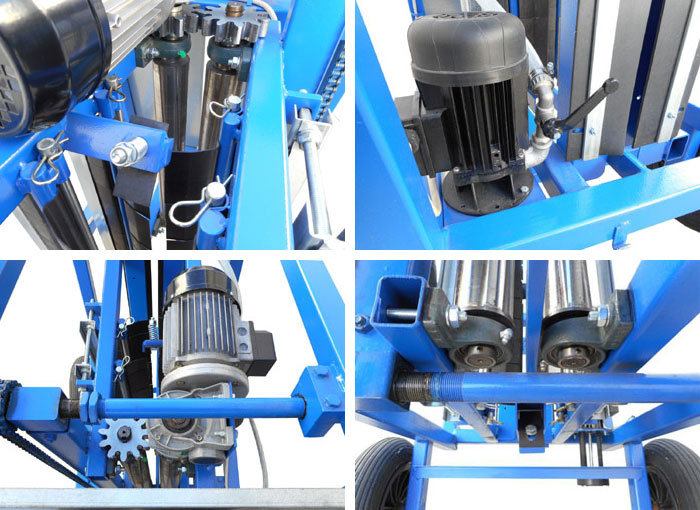

The Puli-Pan machine revolutionizes the wooden panels cleaners sector and combines extraordinary performance with low prices.

This machine results from a multi-years experience of G.B.M. previous models.

The machine, each component and each gear are patented.

The machine can clean panels with an advancement speed about 6 meters per minute.

The ratio-motor 0.5 Hp (on three-phase model) or 0.75 Hp (on single-phase model) furnished with the machine for traction, synchronized and keyed directly into the driving rollers, allows for the complete elimination of chains,thereby eliminating all maintenance and adjustments.

The cleaning of the table begins in the driving rollers, which, thanks to the rounded and helical milled grooves along the surface, crush the coarser cement residues.

The first couple of scrapers do the preliminary cleaning and the second one finishes it.

Thanks to the vertical position of the panels the residuals of cement falls down inside a container.

The following release agent jets clean the panels and wipes away the residual dust inside the container filter and the rubber spatulas take off the excessive release agent.

The rubber sheaths remove the excess release agent.

The scraper discs are made of hardened steel for a high durability.

The thin thickness of the scraper permits a perfect cleaning with a minimum pressure on the board in order to protect the surface resin.

In practice there is the same result as accurate hand cleaning. Each scraper disc is independent of the other and thanks to the rod can be regulated in a different way on the dirty surface.

The particular shape of the scraper disc makes both edges usable with smooth rotation, as they are put together with a simple push.

The machine, each component and each gear are patented.

SIZE:

Length 1960 mm

Width 860 mm

Max height 1300 mm

Total weight 230kg approximately.

Videotutorial

Wooden panels clearer catalogue

Do you want to obtain the catalog of GBM wooden panels cleaner and beam cleaner machines?

GBM H20 beams and formwork sheets catalogue

Would you like to see the full catalogue of GBM H20 beams and panels?

Download the full catalogue in pdf format (3 MB)

Or go straight to the online version.

Content of the catalogue? General information and technical features: type of wood, weight, dimensions (they come in various standard lengths), certificates etc.

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)