GBM scaffolding

We - at GBM - have been manufacturing scaffolding for all types of construction site for more than 60 years.

We manufacture bushing-type scaffolding, pin-type scaffolding and pipe-coupling scaffolding.

In need of a safe scaffolding made of steel, certified and easy to assemble?

Types of scaffolding

We - at GBM have been manufacturing scaffolding suitable for all worksite needs for more than 60 years.

Our scaffolding come in the following three types.

Bushing-type scaffolding

Bushing-type scaffolding. The easiest scaffolding to use due to its standardisation and the fact that it is quick to assembly and disassemble.

Pin-type scaffolding

Pin-type scaffolding. Standard scaffolding consists of metal frameworks with predefined height and depth. Quick to assemble, quick to disassemble.

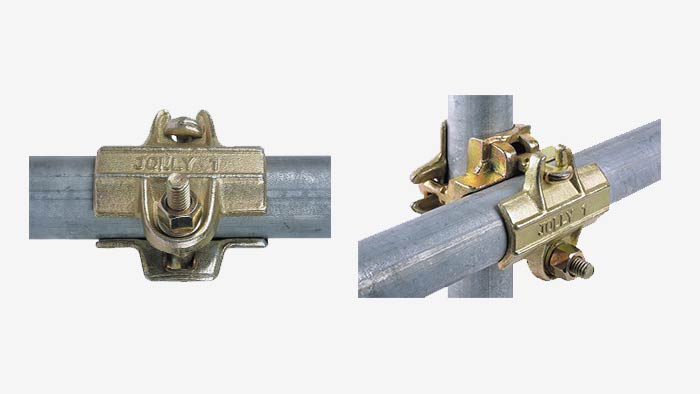

Pipe-coupling scaffolding

Pipe-coupling scaffolding, with variable geometry obtained by connecting pipes by means of special couplings can take any direction and angle.

Mobile scaffoldings

Scaffolding for construction sites: Mobile tubular scaffolding on wheels ideal for housework.

Multidirectional scaffolding

The insuperable system in terms of versatility of use, assembly speed and convenience, also thanks to a wide range of accessories.

GBM scaffolding catalogue

Would you like to view the full GBM scaffolding catalogue?

Download the full catalogue in PDF format (9.9 MB)

Or go straight to the online version.

Or visit the video section of our site to see 3D video tutorials.

Manufacturing GBM building scaffolding.

We - at GBM - have been designing, manufacturing and selling scaffolding for more than 60 years.

This is why building companies across the world opt for our products.

We - at GBM - have been manufacturing and selling construction scaffolding for more than 60 years.

For years, our scaffoldings have been used across the world for construction and maintenance works; our wide range of accessories will help you solve any challenges you may be faced with at the worksite including external brackets for cantilevered solutions and unloading decks at different heights of the building.

The GBM line of scaffolding comes with diversified scaffolding designed to meet your needs as a constructor.

GBM pin-type and bushing-type scaffolding are just what you need for a safe facade scaffolding that is quick and easy to use.

On the other hand, GBM pipe-coupling scaffolding is the ideal solution for those in need of a variable geometry modular system.

Bushing-type scaffolding, pin-type scaffolding, pipe-coupling scaffolding and modular scaffolding: how do they differ?

Different configurations, same supreme quality.

However, each type is designed to perform at its best in different fields and applications.

Scaffolding is used for different purposes and applications. We - at GBM - manufacture the following main types of scaffolding:

- Fixed scaffolding with prefabricated frameworks: it is obtained by connecting several metal frameworks with standard height and depth on which the bases and parapets are fixed. It is the easiest scaffolding to use. Being standardised, easy to assemble and disassemble, it does not require special manpower skills. However, the user guidelines provided in the respective documents, i.e. the "scaffolding instructions booklet” must be strictly complied with. This category includes:

- bushing-type scaffolding (in which horizontal ledgers and diagonal braces connecting the frame - at the ends - pins to be inserted into the rings - the “bushings” - present on the frames)

- and pin-type scaffolding (in which horizontal ledgers and diagonal braces feature - at the ends - holes to be fitted onto the pins present on the frames).

- Pipe-coupling scaffolding: obtained by connecting the tubes to each other and obtaining this connection by coupling. This is a variable geometry and modular scaffolding that enables reaching any extension, height, and connecting the components thereof in any direction and angle on the three spatial dimensions: its modularity enables adjustment thereof to any façade or product, simplifying if not even enabling activities that would be otherwise almost impossible to perform. However, these advantageous solutions require specialised labour and averagely more assembly and disassembly times.

- Modular scaffolding: conceptually similar to the pipe-coupling scaffolding, the only difference lies in the fact that it provides for the use of pipes with welded washers so as enable mutual connection. This system has become increasingly popular due to the fact that it combines the adaptability and usefulness of the pipe-coupling system with the quickness and concreteness of the prefabricated frame system. These features thereof place it halfway between the two previous types of scaffolding thus representing the ideal solution to enjoy the advantages of using both systems.

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)