Slab H20 beams

GBM's slab beams are currently the most resistant in the market.

Available in various sizes, they are made of solid fir.

About GBM's slab beams

GBM H20 and GBM H20+ slab beams are currently the most resistant in the market.

Available in various sizes, the outer parts are made of selected quality solid fir, comb-like coupled using the finger-joint technology, and with a three-layer core.

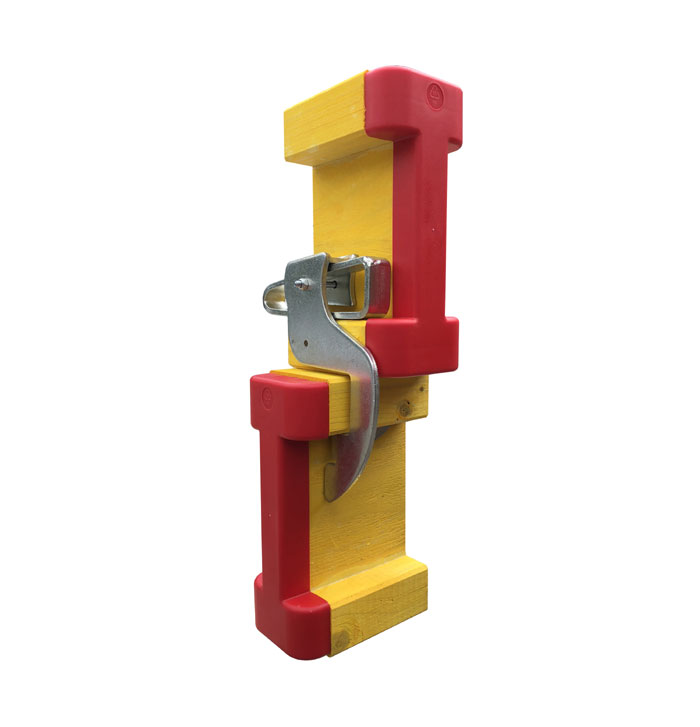

Upon request, they may come in plastic protections so as to reduce the risk of scratching the outer parts of the beams.

Technical features

Below are the features of GBM's slab wooden H20 beams

- Type of wood: fir

- Weight: 4.5 kg/m

- Gluing: melamine resin-based glue, type EN 30, approved for fixing wooden structural components

- External: made of selected solid fir and coupled with 80 x 40 mm section - milled and perfectly calibrated for an optimal assembly with core

- Core: three layers of solid fir

- Surface: treatment with water repellent paint

- Standard length: 1.95 / 2.45 / 2.65 / 2.90 / 3.30 / 3.60 / 3.90 / 4.50 / 4.90 / 5.90 m

- Standard packaging: 50/100 pcs per package

Thanks to their perfect assembly, GBM H20 and GBM H20+ beams can be cut and used at any length.

GBM slab beams technical data

| Dimension | Values (a) | Tolerance (b) |

|---|---|---|

| Beam height | 200 mm | ± 2 mm |

| External height | 40 mm | ± 0,6 mm |

| External width | 80 mm | + 0,8 mm/-1,2 mm |

| Core thickness | 28 mm | ± 1 mm |

a) The values are applied with wood humidity at 12% ± 2%

b) In compliance with the SIST EN 13377:2002 standards

| Certificates | DIN1052-1:1988-04 | DIN1052:2008-12 / Eurocode 5 |

| Resistance | Bending | Load capacity characteristic limit |

| Shear strength | ZUL Q = 11,0 kN | Vk = 23,9 kN |

| Bending moment | ZUL M = 5,0 kNm | Mk = 10,9 kNm |

| Load | - | Rb,k = 47,8 kN |

| Sectional modules (1) | Wx= 461 cm3 | |

| Geometric moment of inertia (1) | Ix= 4.613 cm4 | |

| Modulus of elasticity | E = 10.000 N / mm2 | |

| Shear modulus | G = 600 N / mm2 |

1) The values of the sectional modules and the geometric moment of inertia are applied to new beams. A higher safety value must be used for worn out beams.

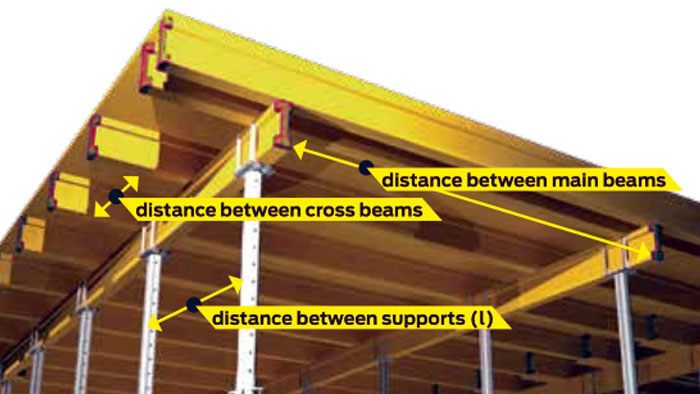

Load table

| | | Distance between crossbeams (m) | Selected distance between the main beams (m) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Floor thickness (cm) | Total load (kN/m2) | 0,50 | 0,625 | 0,667 | 0,75 | 1,00 | 1,25 | 1,50 | 1,75 | 2,00 | 2,25 | 2,50 | 3,00 | 3,50 |

| 10 | 4,38 | 3,70 | 3,43 | 3,35 | 3,22 | 2,93 | 2,72 | 2,50 | 2,31 | 2,16 | 2,04 | 1,93 | 1,70 | 1,45 |

| 12 | 4,91 | 3,50 | 3,24 | 3,17 | 3,05 | 2,77 | 2,57 | 2,36 | 2,19 | 2,05 | 1,92 | 1,82 | 1,52 | 1,30 |

| 14 | 5,43 | 3,32 | 3,09 | 3,02 | 2,91 | 2,64 | 2,45 | 2,24 | 2,08 | 1,94 | 1,82 | 1,64 | 1,37 | 1,18 |

| 16 | 5,95 | 3,19 | 2,96 | 2,90 | 2,79 | 2,54 | 2,35 | 2,14 | 1,98 | 1,85 | 1,66 | 1,50 | 1,25 | 1,07 |

| 18 | 6,48 | 3,07 | 2,85 | 2,79 | 2,69 | 2,44 | 2,25 | 2,06 | 1,90 | 1,72 | 1,53 | 1,38 | 1,15 | 0,99 |

| 20 | 7,00 | 2,97 | 2,76 | 2,70 | 2,60 | 2,36 | 2,17 | 1,97 | 1,82 | 1,59 | 1,42 | 1,28 | 1,07 | 0,91 |

| 22 | 7,53 | 2,88 | 2,68 | 2,62 | 2,52 | 2,29 | 2,09 | 1,90 | 1,69 | 1,48 | 1,32 | 1,19 | 0,99 | 0,85 |

| 24 | 8,05 | 2,81 | 2,61 | 2,55 | 2,45 | 2,23 | 2,02 | 1,84 | 1,58 | 1,39 | 1,23 | 1,11 | 0,93 | 0,80 |

| 26 | 8,57 | 2,74 | 2,54 | 2,49 | 2,39 | 2,18 | 1,95 | 1,73 | 1,49 | 1,30 | 1,16 | 1,04 | 0,87 | 0,75 |

| 28 | 9,10 | 2,67 | 2,48 | 2,43 | 2,34 | 2,12 | 1,89 | 1,63 | 1,40 | 1,23 | 1,09 | 0,98 | 0,82 | 0,71 |

| 30 | 9,68 | 2,61 | 2,43 | 2,38 | 2,29 | 2,06 | 1,83 | 1,54 | 1,32 | 1,15 | 1,03 | 0,93 | 0,77 | 0,65 |

| 35 | 11,25 | 2,49 | 2,31 | 2,26 | 2,18 | 1,90 | 1,59 | 1,32 | 1,14 | 0,99 | 0,89 | 0,80 | 0,66 | 0,56 |

| 40 | 12,83 | 2,38 | 2,21 | 2,17 | 2,07 | 1,74 | 1,39 | 1,16 | 1,00 | 0,87 | 0,78 | 0,70 | 0,58 | 0,49 |

| 45 | 14,40 | 2,29 | 2,13 | 2,07 | 1,94 | 1,55 | 1,24 | 1,04 | 0,89 | 0,78 | 0,69 | 0,62 | 0,51 | 0,44 |

| 50 | 15,97 | 2,22 | 2,03 | 1,96 | 1,84 | 1,40 | 1,12 | 0,94 | 0,80 | 0,70 | 0,62 | 0,56 | 0,46 | 0,40 |

| 55 | 17,54 | 2,15 | 1,93 | 1,87 | 1,69 | 1,27 | 1,02 | 0,85 | 0,73 | 0,63 | 0,56 | 0,51 | 0,42 | 0,36 |

| 60 | 19,11 | 2,07 | 1,85 | 1,75 | 1,56 | 1,17 | 0,94 | 0,78 | 0,66 | 0,58 | 0,52 | 0,46 | 0,39 | 0,33 |

| 65 | 20,68 | 1,98 | 1,72 | 1,62 | 1,44 | 1,08 | 0,87 | 0,72 | 0,61 | 0,54 | 0,48 | 0,43 | 0,36 | 0,31 |

| 70 | 22,26 | 1,91 | 1,60 | 1,50 | 1,34 | 1,01 | 0,81 | 0,66 | 0,57 | 0,50 | 0,44 | 0,40 | 0,33 | 0,28 |

| 75 | 23,83 | 1,85 | 1,50 | 1,41 | 1,25 | 0,94 | 0,75 | 0,62 | 0,53 | 0,47 | 0,41 | 0,37 | 0,31 | 0,27 |

| 80 | 25,40 | 1,76 | 1,41 | 1,32 | 1,17 | 0,88 | 0,71 | 0,58 | 0,50 | 0,44 | 0,39 | 0,35 | 0,29 | 0,25 |

| 85 | 26,97 | 1,65 | 1,32 | 1,24 | 1,11 | 0,83 | 0,66 | 0,55 | 0,47 | 0,41 | 0,37 | 0,33 | 0,27 | 0,23 |

| 90 | 28,54 | 1,56 | 1,25 | 1,17 | 1,05 | 0,79 | 0,62 | 0,52 | 0,44 | 0,39 | 0,35 | 0,31 | 0,26 | 0,22 |

| 95 | 30,11 | 1,48 | 1,19 | 1,11 | 0,99 | 0,75 | 0,59 | 0,49 | 0,42 | 0,37 | 0,33 | 0,29 | 0,25 | 0,21 |

| 100 | 31,69 | 1,41 | 1,13 | 1,06 | 0,94 | 0,71 | 0,56 | 0,47 | 0,40 | 0,35 | 0,31 | 0,28 | 0,23 | 0,20 |

Our worksites

Here are some examples of our construction sites. Click here to visit the complete gallery

Videotutorial

Technical data sheet

As a tool, the GBM slab H20 beams technical data sheet is useful for worksite operators. The technical data sheet instructs the operator on the main features of the beams.

Download the GBM slab H20 beams technical data sheet in pdf format (0.3 MB)

.

GBM's beams and panels catalogue

Would you like to see the full catalogue of GBM's beams and panels?

Download the full catalogue in pdf format (3 MB).

Or go straight to the online version.

Content of the catalogue? General information and technical features: type of wood, weight, dimensions (they come in various standard lengths), certificates etc.

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)