Formwork panels

Indispensable for any construction site.

GBM’s formwork panels consist of three coated layers of wood.

About GBM's formwork panels

GBM formwork 3ply panels are built with three layers of wood obtained from fir and spruce trees grown in sustainable forests.

STRUCTURE:

Our panels are made with a 3-ply structure 9+9+9 mm, without frame.

This means that the mechanical properties of our panel are the same and unchanged even if you cut the panel.

The outer plies that are in touch with the concrete are thicker (9mm vs 6mm) and will allow the panel to last longer.

Lamellas of GBM panels are prepared from a glulam monolitic beam having a smaller width which improves the resistance of the panel and automatically reduces the maximum dimension of accepted knots.

SURFACE FINISH:

Our panels have a melamin finish, just like other panels, but having a greater quality of raw material we can provide it with natural color finish. Of course we can also provide with the

classic yellow finish.

The reason why yellow is used is to cover possible aestethical defects of the

wood, because yellow tends to uniform the view.

We are sure enough of our quality that we offer it with

natural finish. This finish is also optimal for at sight concrete.

EDGES:

We are introducing a polyuretane protection on the longitudinal edges as an optional. This option will allow a perfect smooth contact of the panels edges and it will improve the concrete finish.

CUSTOMIZATION:

We can customize our panels with the following options:

- Name printed on the top face of each panel - standard will be with day and hour of production for perfect production tracking;

- Name / logo printed on each bundle

- Selection of colors for the edges.

Technical features

Below are the features of GBM shuttering panels

- Wood type: spruce and red fir

- Wood humidity: 12% +/-2%

- Thickness: 21mm; 27mm

- Weight:

- 21 mm = 10 kg/m2;

- 27 mm = 12,3 kg/m2;

- Protection surface: highly resistant melamine resin coating

- Standard packaging:

- 21 mm: 100 pcs per package

- 27 mm: 80 pcs per package

GBM formwork panels technical data

| Thickness mm | 27 | 27, optional | 21, optional |

| Width mm | 500 | 200, 250, 300, 350, 400, 450 | 500 |

| Length mm | 1000, 1500, 2000, 2500, 3000 | 3000 | 1000, 1500, 2000, 2500, (3000) |

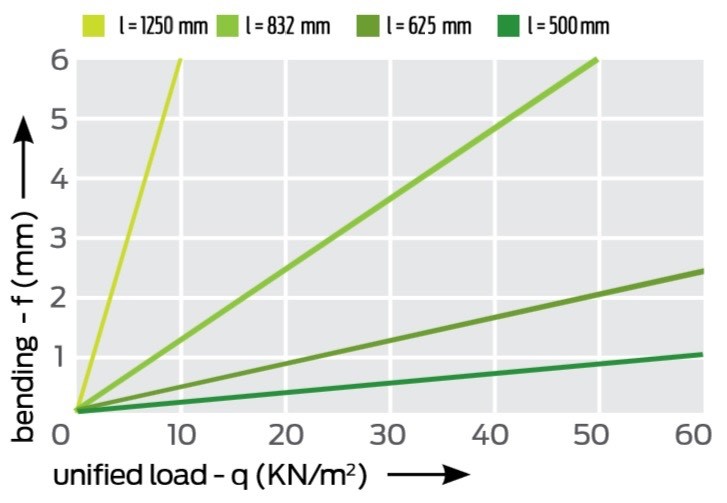

The diagram shows how the panel reacts upon loading, considering the interval spaces between one support element and the other.

Q stands for uniform load (in kN/ m2 unit).

I stands for interval space between the support elements.

f is the folding calculated in mm.

Our worksites

Here are some examples of our construction sites. Click here to visit the complete gallery

Technical data sheet

As a tool, the GBM formwork panels technical data sheet is useful for worksite operators. The technical data sheet informs the operator about the main features of the panels.

Download the GBM formwork panels technical data sheet in pdf format (1 MB)

.

Download the GBM formwork panels' assembly manual in pdf format (3.7 MB)

.

GBM's beams and panels catalogue

Would you like to see the full catalogue of GBM's beams and panels?

Download the full catalogue in pdf format (3 MB).

Or go straight to the online version.

Content of the catalogue? General information and technical features: type of wood, weight, dimensions (they come in various standard lengths), certificates etc.

Related products

News

GBM's shipbuilding scaffoldings

Props required to sustain a slab: guidelines on how to establish distances, classes and quantities.

Multidirectional scaffolding GBM certified EN 17067:2013

GBM Contacts: info, prices & quotes

Would you like further information on GBM products? Ask anything!

Italiano

Italiano English

English Deutsch

Deutsch Français

Français Português

Português Polski

Polski Български

Български Română

Română Español

Español Русский

Русский Српски

Српски Hrvatski

Hrvatski Slovenski

Slovenski Shqip

Shqip Magyar

Magyar English (US)

English (US)